SmartSPRAY is an automatic teat spray system for rotary platforms.

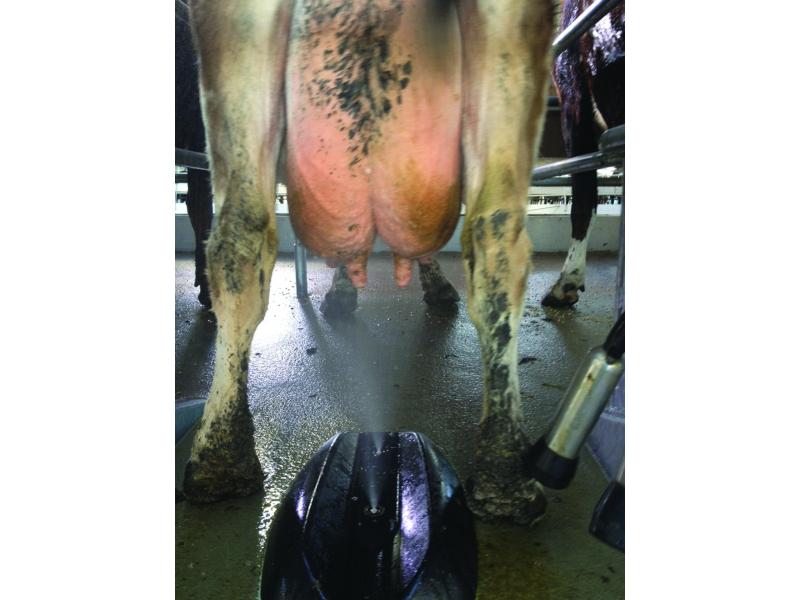

SmartSPRAY replaces the need for manual teat spraying and teat dipping, while ensuring maximum coverage regardless of the cow’s position in the bail.

SmartSPRAY is signalled by the electronic cup remover to spray soon after the cups have been removed. This ensures the udder is sprayed while the teat orifice is still open, and typically in a sheltered area of the shed to prevent wind drift.

No operator input is required during milking other than filling the tank with teat spray. The tank is mounted underneath the rotary.

SmartSPRAY can be retrofitted to existing rotaries with an interface module that allows it to receive signals from any brand of electronic cup remover.

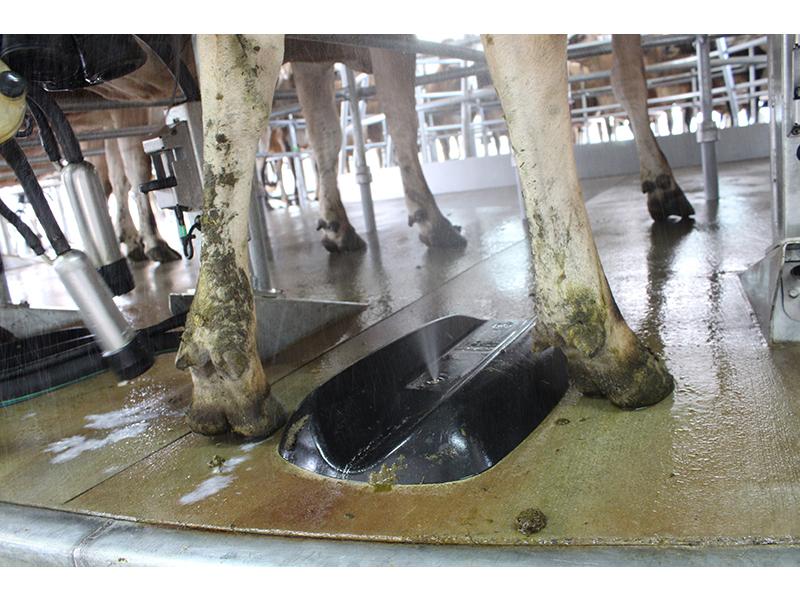

SmartSPRAY Bullet

A SmartSPRAY Bullet is positioned in every bail. With two adjustable spray nozzles these can be rotated to cater for a wide variety of cow sizes.

SmartSPRAY Tank

A SmartSPRAY tank is made from chemical resistant polymers and has an integrated compressed air spray pump. With a 125L capacity it typically holds up to 4 days of teat spray.

SmartCONTROL

SmartCONTROL is the touch screen panel that controls the settings of all our premium new generation technology including SmartSPRAY’s spray delay and duration settings.

Features:

• Bullets position cows legs for easy cluster attachment

• Dual nozzle SmartSPRAY Bullet at each bail

• Adjusted from SmartCONTROL touch screen

• Spray duration, delay and pressure can be adjusted to suit

• Powerful compressed air pump system with pressure gauge

• Precision, chemical resistant solenoid valves

Benefits:

• Spray is automatically triggered by ECR-S or ECR Plus once cow has finished milking

• Won’t spray if a cow kicks cups off — will only spray once milking has been completed

• Ideal for single operator dairies

• Uses less teat spray than other systems

• Maximises spray success — spray occurs while teat orifice is open

• Adjustable nozzles ensure optimum spray coverage

• Sprays every cow, every time